Global Garnet hard rock abrasive products come in a variety of grades, from coarse through to fine, and can be used for many industrial applications and across many industries.

through to fine, and can be used for many industrial applications and across many industries.

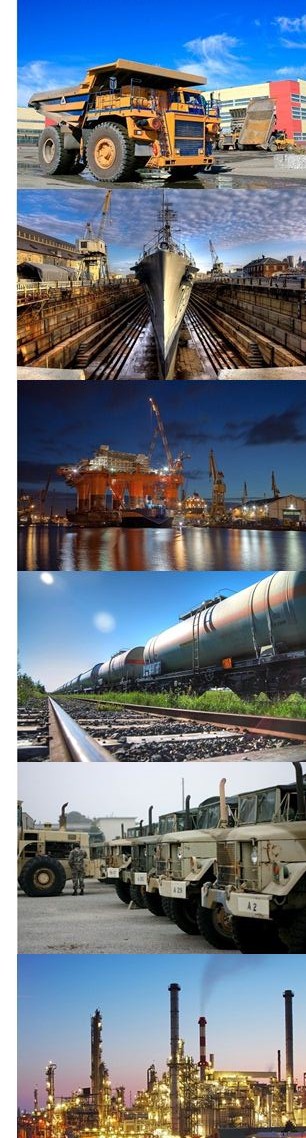

Hard rock garnet is commonly used for many diverse applications, such as plant maintenance, offshore oil rigs and oil field applications such as storage tanks, steel structures and pipelines.

Our products are also used extensively at shipyards worldwide for heavy coatings, tightly adherent mill scale and rust with precise control of feathering when blasting weld seams and for construction damage.

Facility maintenance, turnaround jobs and blast room work are just a few other applications where our range of hard rock garnet abrasives help lift our customers productivity, reduce consumption and minimalize the clean-up process.

Industrial painters highly value hard rock garnet as its high-quality surface finish, uniform profile and high-durability allows for maximum re-use for blast room applications.

Industrial Applications – Blasting

Global Garnet has high performance grades of hard rock garnet suitable for any Blasting Abrasives application or industry, including but not limited to the following;

- Heavy Equipment Repair

- Industrial Painting Contracting

- Shipbuilding and Ship Repair

- Mining Trucks & Equipment

- Blast Rooms, Chambers or Cabinets

- Petrochemical

- Powder Coating

- Denim Blasting

- Industrial Plant Maintenance

- Railcars & Wagons

- Stone Building Facades and Monuments

- Aircraft Maintenance

- Graffiti Removal

- Military Assets

- Offshore Oil Rigs

- Water & Fuel Tanks

- Boilers

- Turbine Repair

- Plant Machinery

- Pipelines

- Steel Structures & Bridges

- Oil field Applications

Industrial Applications – Water Jet Cutting

The Global Garnet range of quality Water Jet Cutting Abrasives can be used for a wide range of cutting applications and materials, including but not limited to: Tile, Glass, Stone, Kevlar, Granite, Carbon Steel, Copper, FRP/CRP, Marble, Rubber, Wood, Aluminum and Stainless Steel.